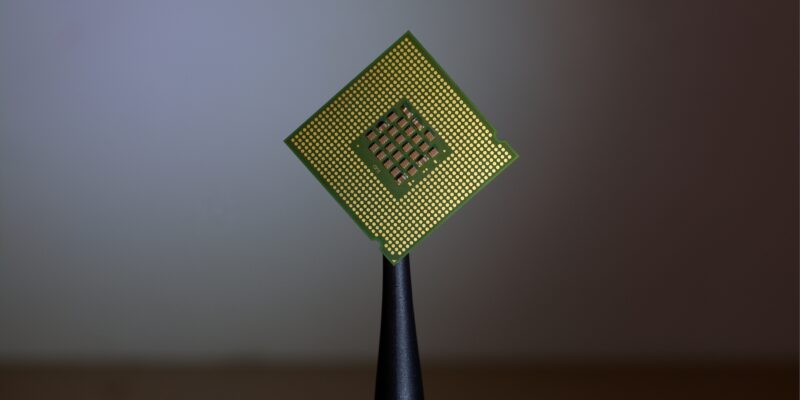

The Chip Shortage Is Still Looming Over the Auto Market. What Now?

In the past, a vehicle’s exclusivity was an intentional move from manufacturers. Now, they don’t really have a choice. The semiconductor chip shortage is at the core of many of the auto industry’s problems.

The auto chip shortage is to blame for rising used car costs

The global population has yet to see the full long-term impacts of the COVID-19 pandemic. However, some of them are already coming to light. The chip shortage started months ago and has the potential to last for years as engineers get on track. This is rippling out into the auto manufacturer line, where cars are able to be completed except for one tiny piece of metal.

In the meantime, buyers are flocking to the pre-owned market. In the first half of March, the average wholesale used vehicle price rose 3.74%. At the time, the index for the market rose 8% year-to-date and 24% year-over-year.

Auto manufacturers met at the White House in April to discuss the chip shortage

Jim Farley from Ford Motor was among numerous CEOs to attend a virtual summit at the White House in April. Afterward, leaders from GM and Stellantis joined in on the conversation. President Joe Biden has committed to helping resolve the auto chip shortage, with domestic company Intel to begin automotive semiconductor production within the next 6–9 months.

The auto industry has a lot to lose, but so do other sectors

I suspect it’s related to the global semiconductor shortage. Any critical chip could be a problem — wifi, Bluetooth, some amplifier or power regulator or other, or the higher profile ones like CPU/GPU/RAM.

I know chip shortages are clobbering the auto industry right now.

— Patrick Ferland (@fleck99pf) April 29, 2021

Other companies that deal with electronics are suffering the brunt of chip shortages as well. This includes laptop, TV and smartphone manufacturers. However, it also includes critical medical supplies such as pacemakers, blood pressure monitors and MRI machines.

If anything, this auto chip shortage just goes to show how fragile the supply chain is. The biggest semiconductor makers are in Asia (Samsung Electronics, Taiwan Semiconductor Manufacturing Co. and SK Hynix Inc.). Of course, there’s also Intel—but their slow innovation on the microchip front isn’t helping Americans any.

Infrastructure development for domestic chip production could help save the auto market and all the other industries impacted by the chip shortage over the next few years.

The auto chip shortage has a real ripple effect

The length of the semiconductor shortage is still unclear, though some experts say it could last years. So far, thousands of manufacturing plant employees have been laid off until enough supplies are in to meet consumer demand. Stock prices for public companies are at risk of losing their above-market-average growth.

Meanwhile, Tesla is restructuring its use of Samsung microchips, instead switching to microcontrollers and new firmware from other suppliers. Will other automakers follow suit, or will the chip shortage lead to a total stall in the auto market before too long?

Crazy times!