3D Printing in the Automotive Industry

The automotive industry is in a transitionary period of change. Hybrid, electric, and self-driving cars have been easily integrated into our daily lives, and there is more change to come. As climate change is becoming more prevalent, automakers are looking for new processes and technologies to make their cars more environmentally friendly and as well as innovative.

The 3D printing process is one of the ways technology is revolutionizing the automotive industry. Historically, 3D printing technology has been used for engineering applications such as creating 3D prototypes. But automotive manufacturers have now applied it to critical processes such as designing, developing and manufacturing their vehicles.

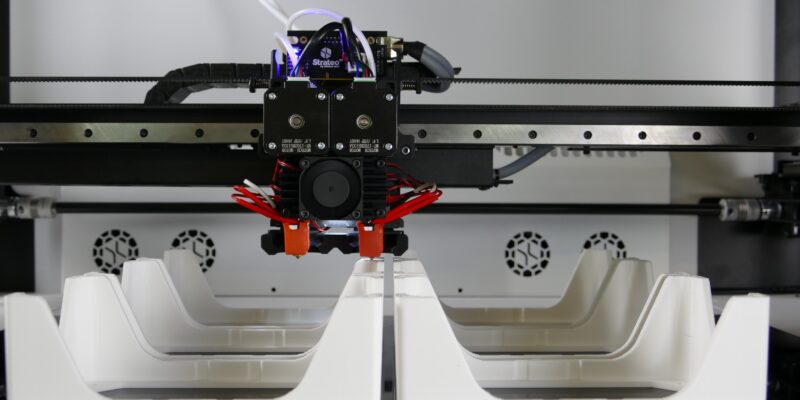

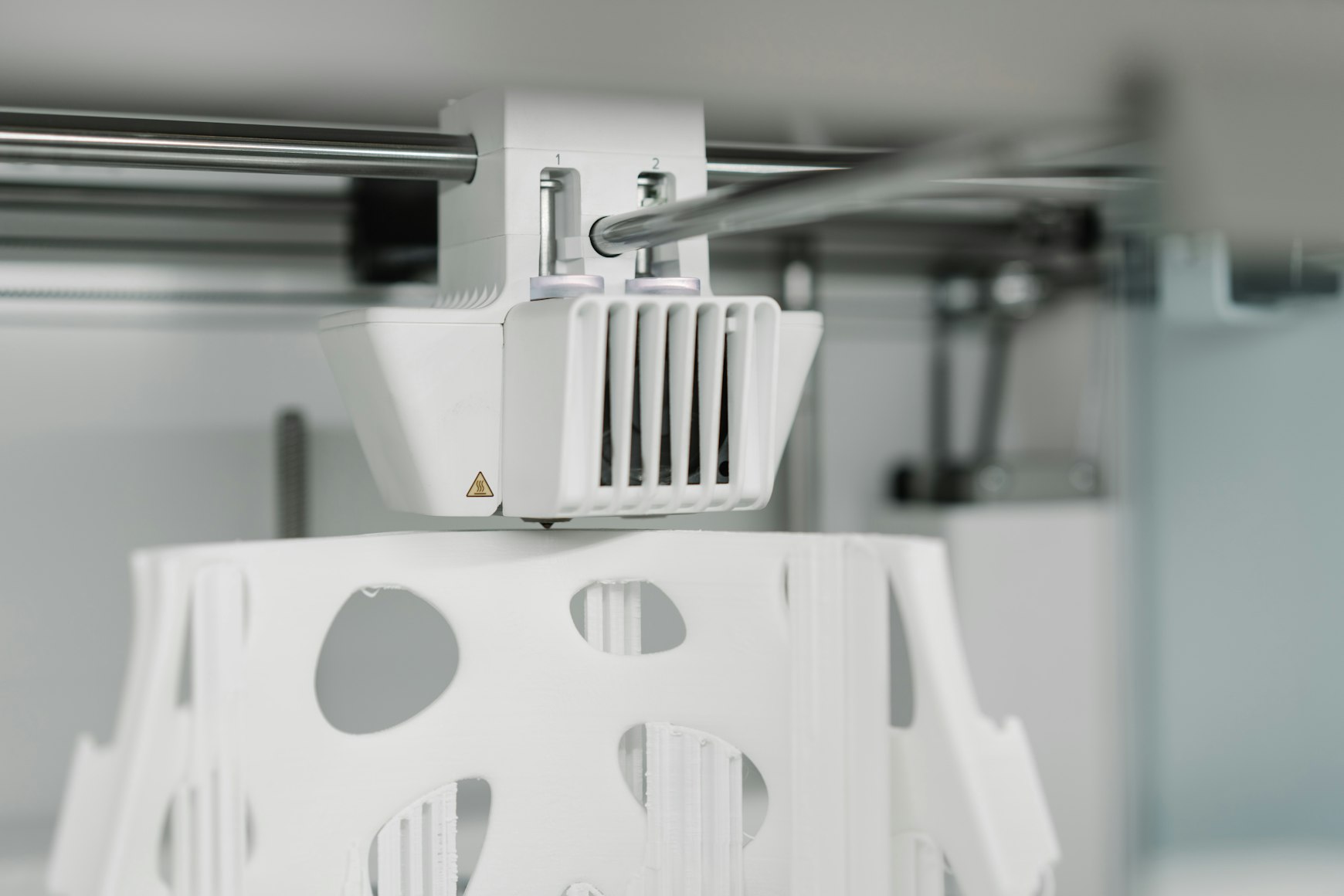

In simplistic terms, 3D printing is a technology that involves creating a three-dimensional object. Firstly, the product is designed on a computer. Once the design is finalized, it is created using a method known as additive manufacturing. This is where the object is constructed by building up thin layers of materials and laying them one by one until the part is complete.

Understanding the utility of 3D printing technology

Over the last few years, the primary application of 3D printing in the automotive industry is to produce prototypes like in engineering. It can be used in several ways, from checking if the small parts of the car work well together to a full-scale replica of the new design. It gives manufacturers a real-time, full-scale, 360-degree view of their unique part or vehicles before it goes into manufacturing.

This prototype shows designers and manufacturers any details or parts of the car that doesn’t work or aren’t aesthetically pleasing before it is mass-produced. For example, Ford used a prototype for the lettering on the rear of the Ford Puma. It lets the designers see the lettering in different lighting at different times of the day.

Now, 3D printing technology is becoming mainstream and more affordable, and it is being brought to manufacturing plants to be used for various applications that change how automakers design and produce their cars. Some of the applications include:

Lightweight car parts

Supercars like the Bugatti Bolide have 3D printed certain car parts to reduce the car’s overall weight, making it faster. The BMW i8 is known for containing a vast amount of 3D printed parts, including its bonnet, which is now stronger but lighter. Also, using 3D printing in the manufacturing process of a vehicle can make it up to 20% cheaper and up to 45% quicker to build. It can save automakers money and time without compromising the quality of the vehicle.

Improving engine performance

3D printing and prototyping the parts within an engine design gives the mechanics and designers a chance to review how the engine could work. If any design flaws or automotive problems are found, they can be resolved or redesigned to ensure optimum performance from the vehicle’s engine. It can also be used for parts that are historically awkward in shape or difficult to construct. 3D printing these parts will give a more precise design that will contribute to the high performance of the car’s engine.

Customized vehicle parts

While 3D printing can be used to construct essential vehicle parts, it can also be used for a fun application. Car enthusiasts use 3D printing for the customization of components needed for vehicles like supercars, collectibles, and vintage cars. Manufacturers can tailor the parts to specific vehicles, and the beauty of 3D printing is they can add any personalization or bespoke factor to any car part.

It is also a vital service to keep vintage cars in use. As years go by, parts become harder and harder to acquire. But with 3D printing, they can be constructed and added to the car, keeping automotive history alive.

Spare parts

Spare parts

Over 100,000 parts are made for a single vehicle, with over 4,000 spare parts produced yearly for that same vehicle. Due to this demand, automotive companies are using 3D printing to create spare parts. Once the design is approved, spare parts of the vehicle can be made more quickly and in real-time, when needed instead of being mass-produced where there is a chance they might never be required. This way of manufacturing is greener and more environmentally friendly than historical practices.

3D printing for cars

These new applications of 3D printing will change how the automotive industry manufactures and designs vehicles. So when will the first fully 3D-printed car be sold to the public?

In the early 2010s, there were a lot of rumors about 3D printing large-scale roadworthy cars. But since then, automakers have been focusing on using the technology to mass produce structural components. This includes chassis, bodies, and seats. No automotive company has entirely made one of these vehicles, but some are close to production. Examples include Divergent 3D with the “Czinger 21C Hypercar” and XEV with the “Yoyo.”

3D Printing has become an essential manufacturing process in both expensive supercars and everyday sedans. It is such as versatile, inexpensive, and green technology. It is a way of producing quality engineering that is better than the traditional alternatives. Experts agree it won’t take long for automakers to make it the primary way of designing and manufacturing vehicles.

Spare parts

Spare parts